Aguahoja III

2021–2022

Cambridge, MA + San Francisco, CA

︎

︎︎︎︎︎︎︎︎︎︎

︎︎︎

Aguahoja III was constructed in 2022 for display in the San Francisco Museum of Modern Art’s exhibition Nature X Humanity: Oxman Architects ︎︎︎. The structure is third in a series of prototypical towers designed to demonstrate the large-scale 3D printing of organic materials. Each structure is composed of an organic skin bound to a synthetic photopolymer skeleton and stands at 5 meters tall.

The structure’s skin is made from three of nature’s most abundant materials – cellulose, chitin, and pectin. These materials are mixed into hydrogel solutions and 3D printed at room temperature without any synthetic binding agents. By tuning the ratios of each of these components, composites can be printed that are flexible and tough like leather or strong and rigid like wood. Furthermore, just as in nature, these printed composites retain their ability to react to environmental changes in temperature and humidity.

By avoiding the use of synthetic additives and using minimally refined organic matter, the organic composites printed for Aguahoja retain their ability to be decomposed and digested by organisms, transferring the nutrients and energy within them to fuel new growth. In this way, Aguahoja aims to bridge the gap between humans and non-human ecosystems, pointing towards a future where the grown and the made unite.

Realized in collaboration with OXMAN and the Mediated Matter Group at MIT Media Lab ︎

Project Team ︎

Neri Oxman ︎︎︎, Nic Lee ︎︎︎, Felix Kraemer︎, Hannah Gazdus

Substructure Fabrication︎

Stratasys, Ltd., Stratasys Direct Manufacturing

Acknowledgements ︎

MIT Media Lab, Stratasys Ltd., Emerson Collective, GETTYLAB, Robert Wood Johnson Foundation, Stratasys Direct Manufacturing, San Francisco Museum of Modern Art

Press

Dezeen︎︎︎

The Economist ︎︎︎

︎

The structure’s skin is made from three of nature’s most abundant materials – cellulose, chitin, and pectin. These materials are mixed into hydrogel solutions and 3D printed at room temperature without any synthetic binding agents. By tuning the ratios of each of these components, composites can be printed that are flexible and tough like leather or strong and rigid like wood. Furthermore, just as in nature, these printed composites retain their ability to react to environmental changes in temperature and humidity.

By avoiding the use of synthetic additives and using minimally refined organic matter, the organic composites printed for Aguahoja retain their ability to be decomposed and digested by organisms, transferring the nutrients and energy within them to fuel new growth. In this way, Aguahoja aims to bridge the gap between humans and non-human ecosystems, pointing towards a future where the grown and the made unite.

Realized in collaboration with OXMAN and the Mediated Matter Group at MIT Media Lab ︎

Project Team ︎

Neri Oxman ︎︎︎, Nic Lee ︎︎︎, Felix Kraemer︎, Hannah Gazdus

Substructure Fabrication︎

Stratasys, Ltd., Stratasys Direct Manufacturing

Acknowledgements ︎

MIT Media Lab, Stratasys Ltd., Emerson Collective, GETTYLAB, Robert Wood Johnson Foundation, Stratasys Direct Manufacturing, San Francisco Museum of Modern Art

Press

Dezeen︎︎︎

The Economist ︎︎︎

︎

Aguahoja III demonstrates the capabilities of abundant, organic material stocks to create structural composites

︎

![]()

![]()

Digital Fabrication

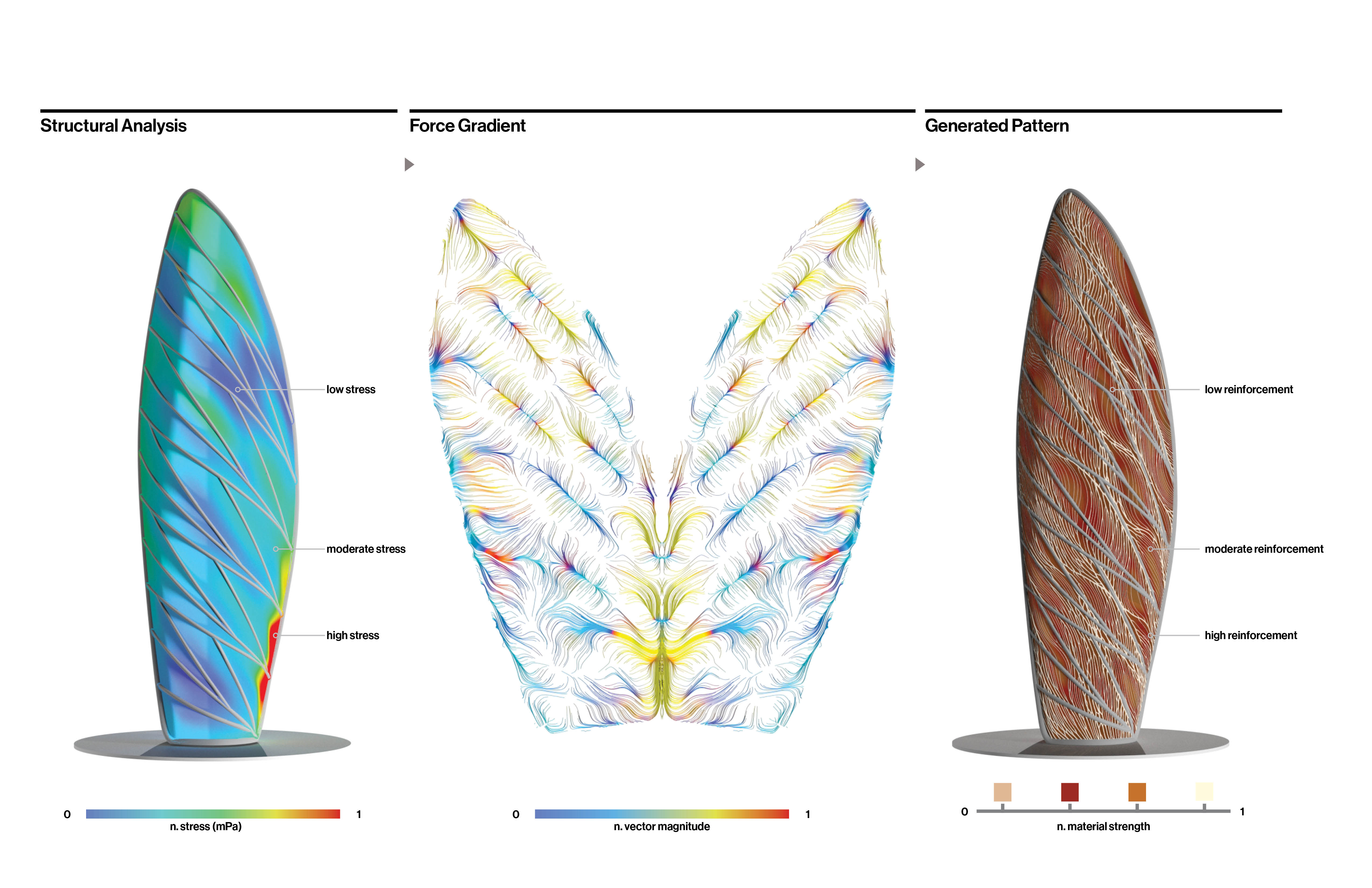

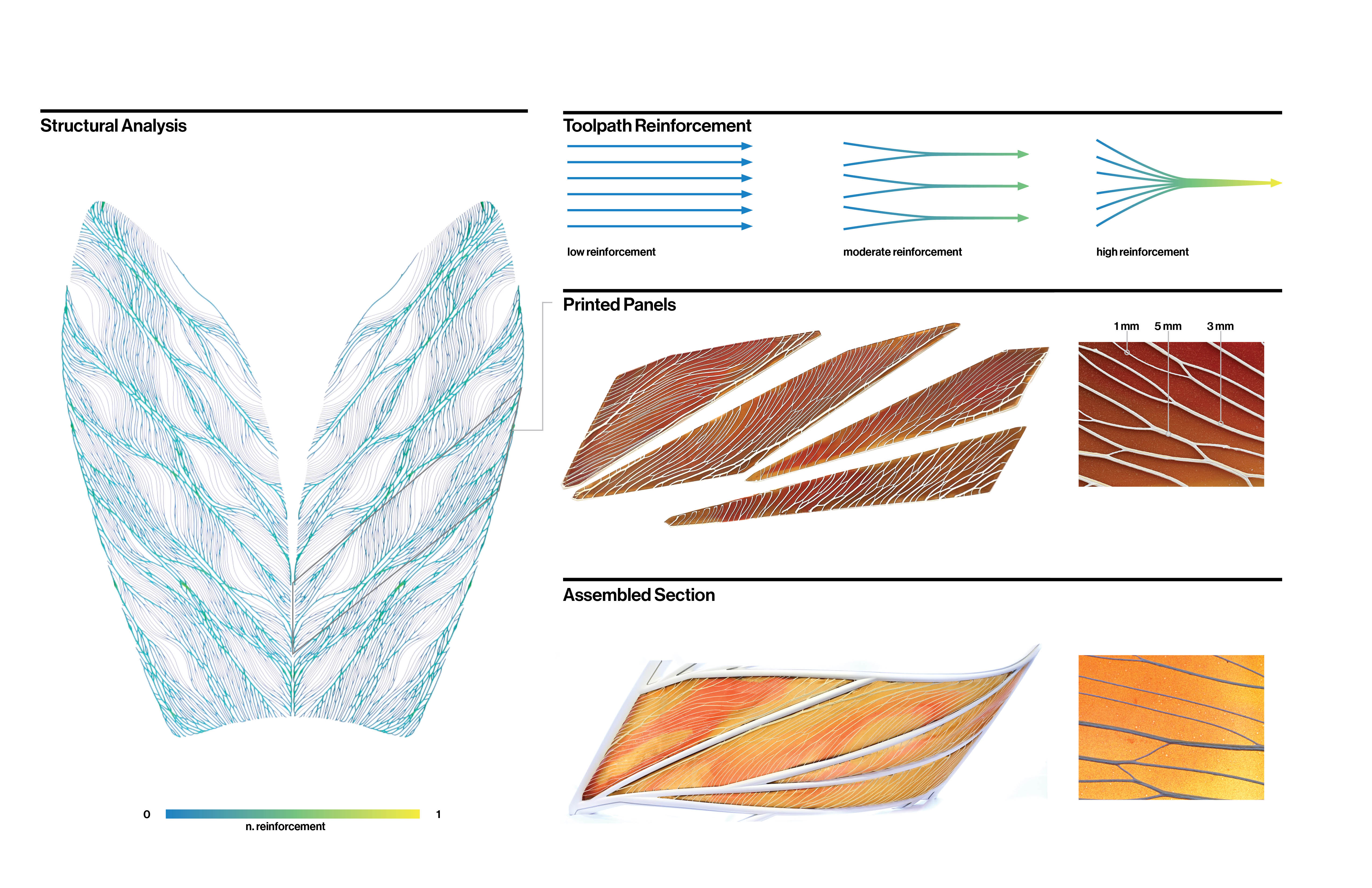

Aguahoja III employs a generative design method that uses structural simulation to assign its distribution of materials and multi-scale geometry. This procedural design method can flexibly assign a biopolymer skin to any input geometry and automatically generate the material combinations, machine parameters, and toolpaths needed to fabricate the structure. This end-to-end pipeline for digital design and fabrication encompasses a flexible, automated system with tight coupling between environmental data, structural performance, and fabrication information.

Aguahoja III employs a generative design method that uses structural simulation to assign its distribution of materials and multi-scale geometry. This procedural design method can flexibly assign a biopolymer skin to any input geometry and automatically generate the material combinations, machine parameters, and toolpaths needed to fabricate the structure. This end-to-end pipeline for digital design and fabrication encompasses a flexible, automated system with tight coupling between environmental data, structural performance, and fabrication information.

︎︎︎︎︎

The structure’s skin is comprised of a flexible base-layer and a rigid layer of reinforced veins. Containing mostly pectin and chitosan, the base-layer of the skin allocates stiff materials in areas of high structural load and flexible materials in areas of high displacement. The veins contain anisotropic cellulose fibers and chitosan which are printed in a pattern that conforms to the gradient of structural stresses to provide maximum reinforcement in areas of high load.

The structure’s skin is comprised of a flexible base-layer and a rigid layer of reinforced veins. Containing mostly pectin and chitosan, the base-layer of the skin allocates stiff materials in areas of high structural load and flexible materials in areas of high displacement. The veins contain anisotropic cellulose fibers and chitosan which are printed in a pattern that conforms to the gradient of structural stresses to provide maximum reinforcement in areas of high load.

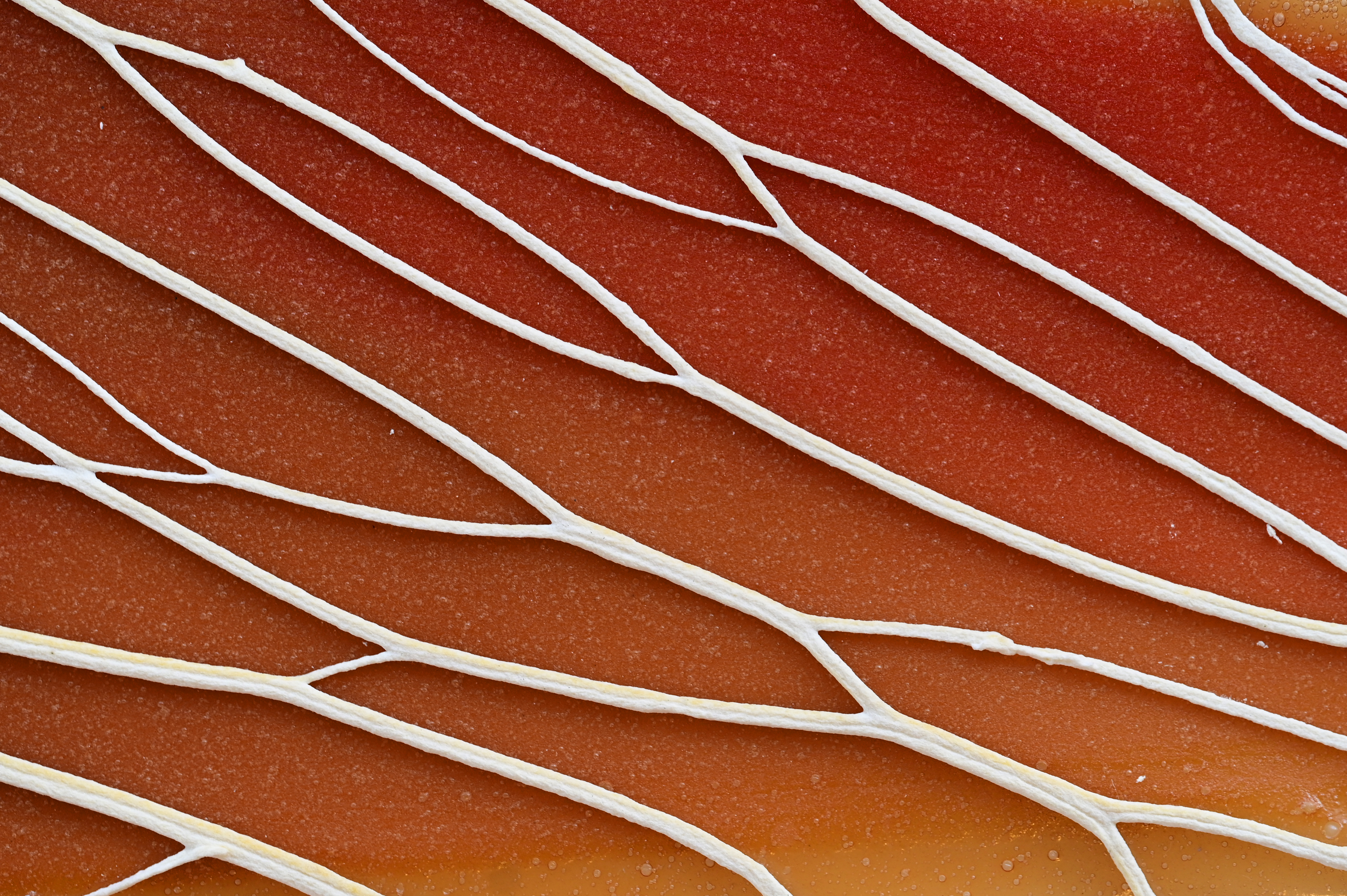

The cellulosic veins along Aguahoja III’s skin are formed through the novel method of Stress-Aligned Anisotropic Printing (SAAP). During the extrusion process, cellulose fibers are shear-thinned to form cross-linked bundles that align to the printed direction. These veins have increased tensile strength along this aligned printing direction. By aggregating multiple groups of veins into thickened bundles, the degree of reinforcement along these paths can be enhanced.

In contrast to conventional 3D printing, Aguahoja’s materials are printed in a semi-liquid state in which there is a high degree of cross-linking between adjacent paths. This leads to the formation of tightly bonded branches which behave as a single monolithic object where multiple paths come together.

Through the use of SAAP, Aguahoja III enables the creation of rigid structural composites with enhanced strength and directed anisotropy from a pallet of sustainable, abundant materials.

Materials

︎︎︎︎︎︎︎︎︎︎︎︎︎︎︎︎

︎